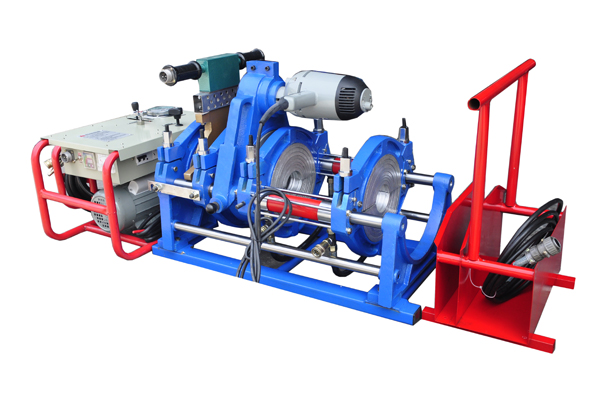

We are offering a huge range of HDPE Pipe Jointing Machines.

Butt fusion welding is the most popular welding method for HDPE piping system, and butt fusion welding machine is an industrial machine which is extensively demanded for welding purposes.

Butt fusion is a thermofusion process which involves the simultaneous heating of the ends of two pipe/fitting components which are to be joined, until a molten state is attained on each contact surface. The two surfaces are then brought together under controlled pressure for a specific cooling time and a homogenous fusion joint is formed. The resultant joint is fully resistant to end loads and has comparable performance under pressure to the pipe itself.An electrical heater plate is used to raise the temperature of the pipe ends to the required fusion temperature. Butt-fusion can be used to join both PE80 and PE100 materials for the pipe sizes of 90mm and above of the same SDR.

The butt welding machines used to weld PE pipes have controls to ensure the welding parameters are strictly adhered to. The following parameters are controlled:

heater plate temperature

>ovality and alignment

interface pressure

bead width

heat soak time

changeover time

Control of these is necessary to ensure premature failure of the weld does not occur. The fieldconditions under which PE pipe is welded have a considerable effect on the strength of the joint. In order to achieve an acceptable weld three elements are essential:

Cleanliness: because contamination will ruin joints

Technique: Most owners of PE pipe systems require that people performing butt welding of PE pipes are qualified by completing a recognized training course.

Correctly designed equipment with proper maintenance: Correct welding temperatures, welding procedures and pipe facing tools must be maintained in tolerance and in good condition.

The resulting joint, if it has been properly made, is as strong as the original pipe and can withstand all the loads applied during routine installation and operation.During the fusion process internal and external ‘weld beads’ are formed. Techniques have been developed to minimize the size of the beads, however as they do not add anything to theoverall strength they may be safely removed if required. The removed weld beads can be inspected as part of a quality control programme.